When it comes to your approach to contingent workforce management, you’re probably like many other companies: Tools and strategies that help you reduce waste and improve productivity are welcome if they help the workplace environment become more satisfying for all. Kanban is one approach that’s been gaining momentum because it focuses on the elimination of wasteful policies and processes that hinder streamlined operations. Take a look at some of the ways your contingent workforce can benefit from Kanban concepts.

What is Kanban?

In the manufacturing industry, Kanban starts from the premise that there’s always a certain amount of waste – in processes, workflows and people. Toyota recognized this in the 1940s and sought a way to eliminate the waste that was forming bottlenecks in its facilities, a concept known as “lean” manufacturing. Managers developed a system of cards (kanbans) that indicated the steps in the manufacturing process and were posted on a board to enable better communication through visuals. The teams at Toyota were better able to physically see what tasks had already been completed, what needed to be done and by when.

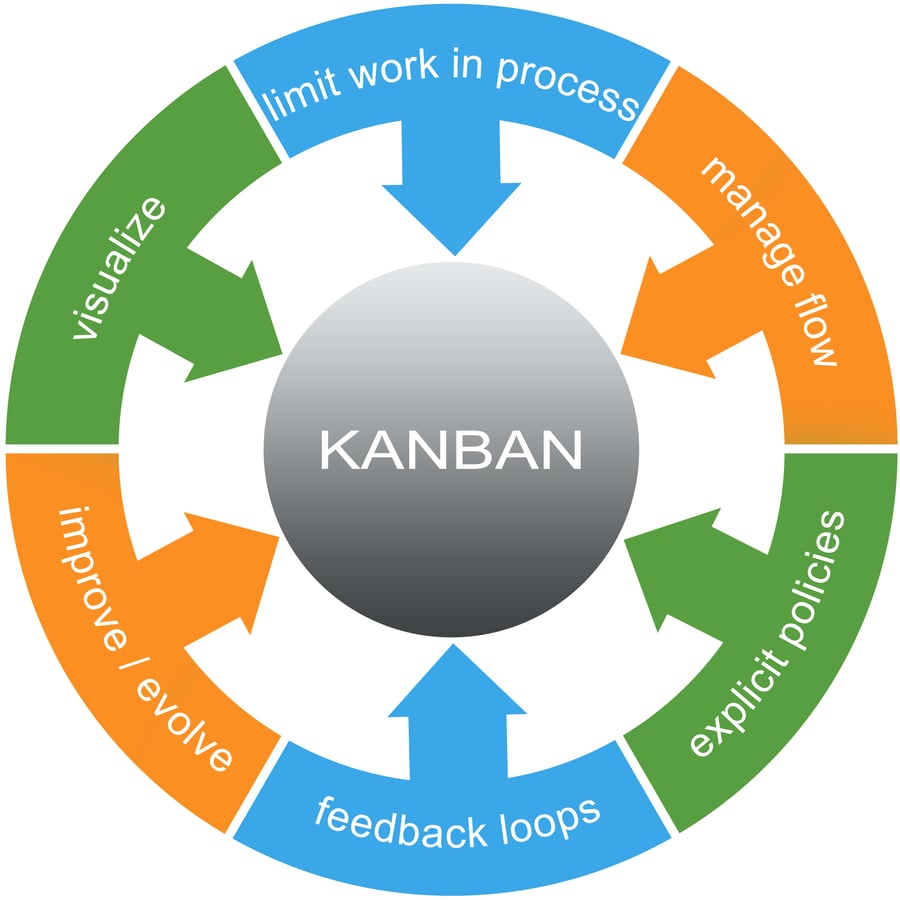

There are four central concepts to Kanban:

- Visualize the workflow and status

- Focus and reduce on work in progress

- Concentrate on the flow of work through the system

- Strive to continually improve

The visual aspect of Kanban makes it so successful: Visibility conveys knowledge. Images are simply better at communicating because the brain processes them faster than text. Kanban creates a picture of your manufacturing process and identifies the status of all tasks, i.e., to do, doing and done. Instead of a five to ten minute conversation or read-through of status, you have the bird’s eye view of the “kanbans” on the board and can strive to reduce the number of them. Seeing how your work is moving through its workflow to a completed product gives context. Armed with this knowledge, managers can identify bottlenecks and resolve problems faster and with less waste.

How does Kanban maximize knowledge to increase efficiency?

Kanban is a methodology that can be applied in manufacturing facilities in almost any format. Color-coded Post-It notes on whiteboards, an advanced workflow management solution that identifies steps, fine-tunes processes, tracks projects, assigns tasks and issues alerts are all viable options. No matter what iteration you’d apply to your contingent workforce, it’s the visibility equals knowledge component that has the greatest impact on efficiency.

By developing an image-based model of your workflow, you can assess the movement and progress of projects through the Kanban system. Every member of your team can view the status and identify clogs in the workflow which increases accountability. A view into your processes also helps with inventory control. Downtime due to stock-outs is devastating and costly for manufacturing facilities. When your contingent workforce has visibility, they have the knowledge they need to communicate and collaborate. Both are critical keys to eliminating waste and boosting efficiency.

Kanban has enterprise-wide benefits for industries across the board, but it can be particularly valuable for companies that retain contingent workers to support their regular employees. Contingent workforce management is simplified when you implement a standardized approach to processes. When you give your contingent employees the guidance they need to complete the tasks you require, they can become vital members of your team.